AutoFire : Anode Bakes Firing Control System

A modern, energy efficient, user friendly control system for Aluminium Smelter Carbon Baking furnaces.

Energy Efficiency – How Many GJ/t was that?

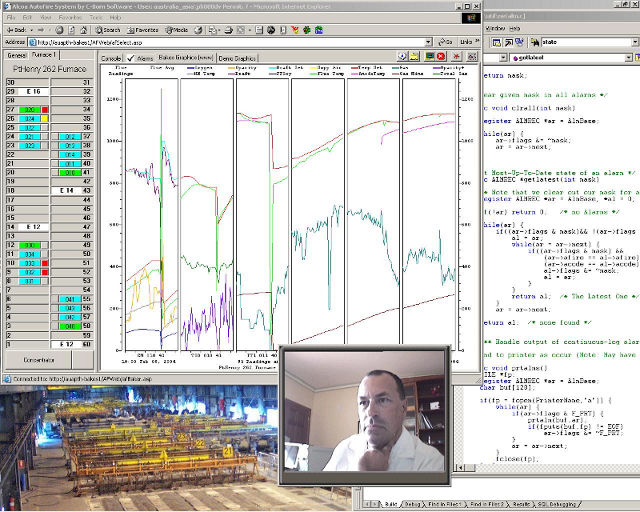

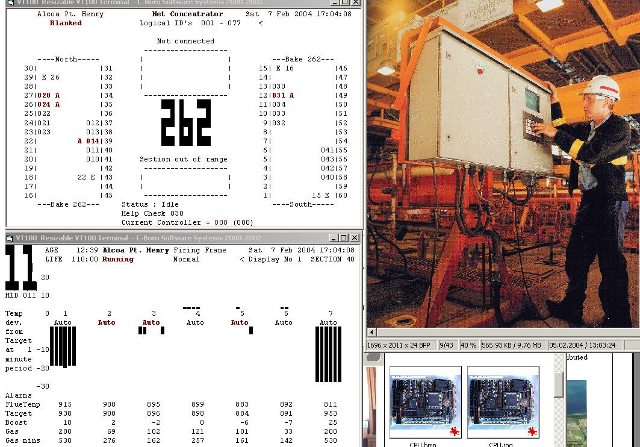

Best Operator Interface Available

Using a modern highly reliable distributed control topology, with color graphics displays at each firing frame, the operator has everything he needs available at his fingertips without having to shuttle between furnace and control room to check on trending and historical data. Process engineers familiar with other implementations have remarked that this feature alone sets our system head and shoulders above anything else currently available. And with an advanced supervisory and control system, utilizing a database backend and a Web based user interface, authorized managers and engineers can monitor and control the process from a dedicated control room, their own office, or anywhere in the world.

Lowest Price, Best Performance

Low overheads and a realistic approach to systems implementation have combined to produce the lowest cost automatic firing control solution available, without any compromise on performance, reliability or safety. The modular system may be installed on a single frame, a fire, or a complete furnace, with the optional supervisory layer operating above that.

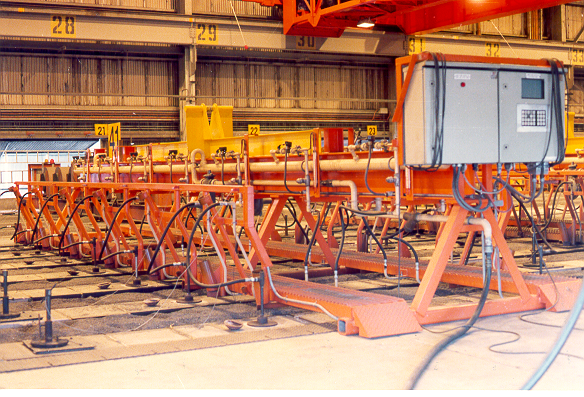

Available as Retrofit

Unlike other systems that require replacement of all the existing manual control equipment in a furnace (firing frames, pipe work, etc) the C-Born system was designed to allow simple retrofitting to existing furnaces. This alone can result in savings of several millions of dollars when automating control of a baking furnace.

Customized for your location

Customized for your location

All locations are different, be it in the fuels used (gas, diesel, bunker-C), the local language (English, Portuguese…), units (metric/Imperial), control strategies, and the like. We can work with your local resources to customize our system to meet local expectations and operation practices. Experiences gained from other plants can be used to optimize your process.

Choice of Hardware for local inventory

When it comes to IO, some plants will have a preference for a particular manufacturer because that equipment is already widely used at the plant, they have experience with it, and they wish to reduce spares inventory. We can work in with that, using equipment from a preferred manufacturer such as Rockwell/AB, Siemens, Sixnet, etc.

Environmental Credentials

An efficient furnace is also a clean one, and our integration of exhaust opacity sensing into the control strategy ensures the most economical use of fuel and air, with the lowest emissions. Smart software allows the detection of opacity for each flue line with only a single opacity sensor per fire, reducing initial and ongoing maintenance costs.

Contact us for any enquiries into AutoFire or any of our other products and service.